Updated 5/2019 with Captain Cache’s Curiosities Podcast episode about 3D printing at the Libraries.

On the second floor of the Old Town Library, tucked over by the computers and printers, sits a large complex looking machine that steadily toils nearly every day printing wondrous, and sometimes strange objects. It’s a machine for the makers, the basement tinkerers, the innovators, and the everyday person.

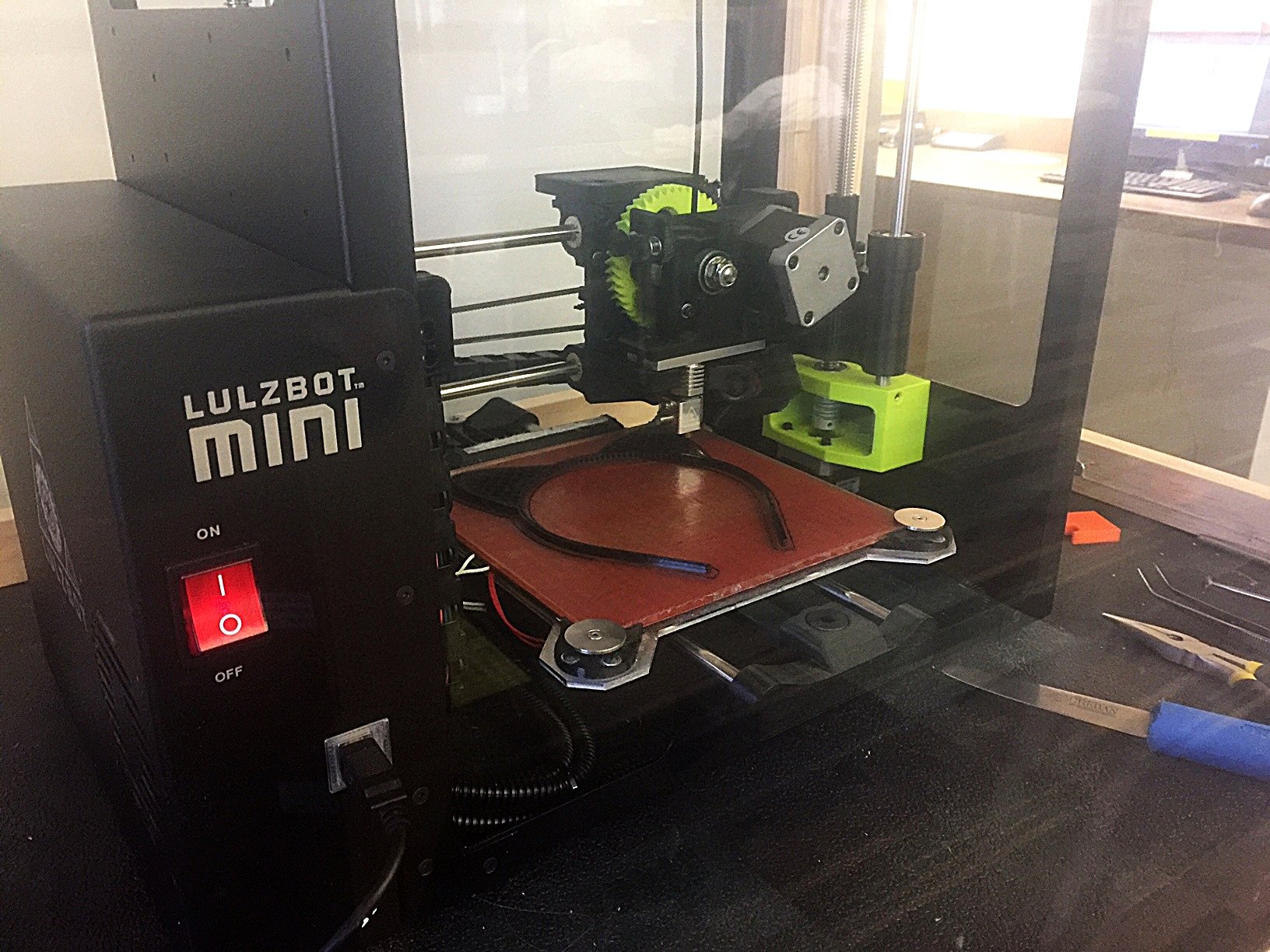

The Old Town Library’s 3D printer, a LulzBot® Mini to be exact, spits out “printed” projects for library users of all ages and technical abilities. On my most recent trip to Old Town Library, sitting waiting to be picked up were chess pieces, a dolphin figurine, an aquarium piece, Halloween costume accessories, and other fun items.

The 3D printer follows instructions from digital modeling programs to gradually build layer upon layer until the object becomes recognizable. The modeling programs are available through the Library District’s 3D Resources webpage, along with access to free tutorials and ready-to-print designs.

While many of the 3D projects created by beginners run closer to bracelets, bookmarks, and keychains, some projects created at the Library have been practical and complex. Earlier this fall, Fort Collins resident Rebecca Fox determined that using the 3D printer would be a great solution to her problem.

After being prescribed a wrist brace by her doctor, Rebecca started to notice a few problems with it: it wasn’t waterproof so when it got wet it become musty and itchy; it was starting to cause a reaction on her skin; and it didn’t really fit snug enough. Taking it off wasn’t really an option, doctor’s orders after all, so she decided to design her own wrist brace using digital modeling software and “print” it on the Library’s 3D printer.

Rebecca describes herself as a relative beginner when it comes to designing with modeling software. She had taken a few courses in high school and undergraduate school that used CAD software and other innovative programs, but she was new to the 3D software.

She jumped right in! Rebecca chose to use the Tinkercad software, available through the Library and online, and began watching tutorials, but she soon found that getting help in-person from Old Town Library staff was the most helpful. She worked with computer assistants like Erik Rock and Sam Scheuerman to sketch an initial design, create it in the modeling software, and then print it.

Rebecca’s wrist brace design used a hex grid or honeycomb pattern infill, the structure that’s printed inside the object giving it strength and shape. The honeycomb infill is generally regarded as a strong and cost-effective choice for 3D printing. Since the cost for 3D printing at the Library District is based on the amount of filament used ($0.10 per gram), choosing infill that doesn’t require as much material while still maintaining its strength helps keep the print cost down.

Rebecca’s wrist brace design used a hex grid or honeycomb pattern infill, the structure that’s printed inside the object giving it strength and shape. The honeycomb infill is generally regarded as a strong and cost-effective choice for 3D printing. Since the cost for 3D printing at the Library District is based on the amount of filament used ($0.10 per gram), choosing infill that doesn’t require as much material while still maintaining its strength helps keep the print cost down.

Through a bit of “trial and error,” Rebecca was able to tweak her initial 3D-printed wrist brace to create one with a comfortable fit with snaps and clean edges. She was even able to make it a bit more fashionable than a typical medical wrist brace. To shape the brace after printing, Rebecca took the flat design, soaked it in hot water very briefly until it was flexible, and then wrapped it around her wrist in the exact shape and size she needed. Because the material can be hot when it comes out of the water, Rebecca wore a latex glove over her skin. This also allowed her a bit of extra room when shaping the brace and kept it from being too tight and chafing. She then adjusted and secured the brace to her wrist using a strip of Velcro found at any hobby or hardware store.

The brace that she now wears was printed over six layers and weighs just ounces, bringing her printing cost to around $3.00. For Rebecca, her custom brace is must more practical for her needs – it’s waterproof and doesn’t have to be removed whenever she’s washing dishes or taking a shower. Plus, it’s comfortable enough to wear all-day. And, let’s be honest, it’s pretty cool looking.

Getting Started with 3D Printing

Interested in learning more about 3D printing at the Library or even creating your own project? Here’s how to get started.

1 Visit the Library District’s online Resources page for modeling software, design libraries, and tutorials.

You can access the Resources page at the library or from the comfort of your own home! The ready-to-print designs from fellow makers on Thingiverse and other sites are perfect for the 3D first-timer, or you can up your skills with free 3D modeling tutorials that will guide you through the process of creating and printing your own project. There’s also a great Introduction to 3D Printing Workshop document created by Steve Undy from the Fort Collins Creator Hub.

2 Choose a 3D model to print as-is, or modify or create one of your own using free software like Tinkercad, Blender, and others.

3 Save your model as .stl file (maximum size 50 MB).

4 Submit your 3D printing request to the Old Town Library computer staff who will get your project underway and contact you when it’s complete. Print times may vary based on size, complexity, and any backlog.

You pay for your project when you pick it up. The cost is $0.10 per gram of filament used to print your model.

The entire Poudre River Public Library District community is welcome to use the 3D printing service. You do not need a library card to print or to watch items being printed on the printer. However, only trained library staff will handle the 3D printer and associated equipment.

For more information about 3D printing, check out our online 3D Printing Overview/FAQ page or call the Answer Center at 970-221-6740. Or feel free to stop by Old Town Library to talk with one of the computer assistants who can also help you with your project.

A Note about 3D Printing at the Library

The Old Town Library regularly maintains and cleans its 3D printer and runs it a well-ventilated area. The Library uses plant-based, recyclable PLA plastic (#7) available in a variety of colors to choose from. PLA creates fewer emissions than the other common filament type (ABS), does not contain BPA, and is generally considered to be a quite safe and bio-compatible material. PLA is used to make common things like plastic cups, and PLA nano particles have even been used for drug delivery, introduced directly into the body. While commercial manufacturers use PLA for cups and other items, it is not recommended that 3D printers be used to create these types of items as they are not food safe.